Welding Equipment, Accessories & Consumables Market: Methods

|

| BrandEssence Market Research |

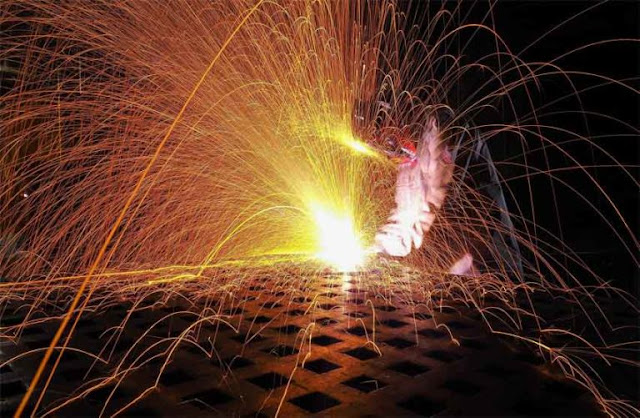

The technique or process which joins materials, ordinarily metals

or thermoplastics, by causing blend, which is unmistakable from cutting down

temperature metal-joining techniques, for instance, brazing and soldering,

which don't soften the base metal are known as welding.

Welding Equipment Accessories

The welding equipment accessories for the welding power source

include the connecting cables or leads, an electrode holder, cable connectors

and the ground clamp. The cables convey the current in welding circuit are very

adaptable and are for the most part made of copper or aluminum wires. These

wires are very found (0.2 mm diameter) and number between 800 to 2500 depending

upon the current carrying capacity of the cable. Aluminum cables are

significantly lighter and weigh just a single third of copper cables yet their

current conveying limits are likewise lower being around 60% that of copper

cables.

Welding Accessories Examples:

- Cylinder Carts

- Strikers - Files

- Hoses - Air, Inert Gas, Oxygen & Acetylene

- Electrode Holders

- Soapstone

- Chipping Hammers

- Ground Clamps

- Bessy Clamps

- Tip Cleaners

- Levels

- Tig Torches & Accessories

- Wire Brushes

- Marking Tools

- Metal Markers

- Carbon Arc Rod

- Anti-Spatter - Bulk, Sprays, & Dip

Welding methods:

- · Oxy-fuel welding

- · Shielded metal arc welding (SMAW)

- · Gas tungsten arc welding (GTAW)

- · Gas metal arc welding (GMAW)

- · Flux-cored arc welding (FCAW)

- · Submerged arc welding (SAW)

- · Electroslag welding (ESW)

- · Electric resistance welding (ERW)

Electric resistance welding (ERW):

a welding process that produces coalescence of laying surfaces

where heat to form the weld is generated by the electrical resistance of the

material.

Electroslag welding (ESW):

an astoundingly profitable, single pass welding process for

thicker materials between 1 inch (25 mm) and 12 inches (300 mm) in a vertical

or close vertical position.

Submerged arc welding (SAW):

uses an automatically fed consumable electrode and a blanket of

granular fusible flux.

Flux-cored arc welding (FCAW):

relatively indistinguishable to MIG welding aside from it utilizes

an extraordinary tubular wire loaded with flux; it can be utilized with or

without shielding gas, contingent upon the filler.

Gas metal arc welding (GMAW):

commonly termed MIG (metal, inert gas), uses a wire feeding gun

that feeds wire at an adjustable speed and flows an argon-based shielding gas

or a mix of argon and carbon dioxide (CO2) over the weld puddle to protect it

from atmospheric contamination.

Gas tungsten arc welding (GTAW):

also known as TIG

(tungsten, inert gas), uses a non-consumable tungsten electrode to produce the

weld.

Shielded metal arc welding (SMAW):

also known as "stick welding" or "electric

welding", uses an electrode that is coated in flux to protect the weld

puddle.

Oxy-fuel welding:

also known as oxyacetylene welding or oxy welding, uses fuel gases

and oxygen to weld and cut metals.

For growing your business in welding equipment, accessories &

consumable market, you need welding equipment, accessories & consumablemarket research report which contains current trends, application, analysis,

etc. BrandEssence Market Research provides Qualitative market research reports.

We can help you to improve your business strategies.

Comments

Post a Comment